Drag Chain Manufacturer in China

Quality You Can Trust, Prices You’ll Love

Lower MOQ

More Flexibility

Various Specifications

Support Customization

Easy to Disassemble

Quality Guaranteed

Hot Products

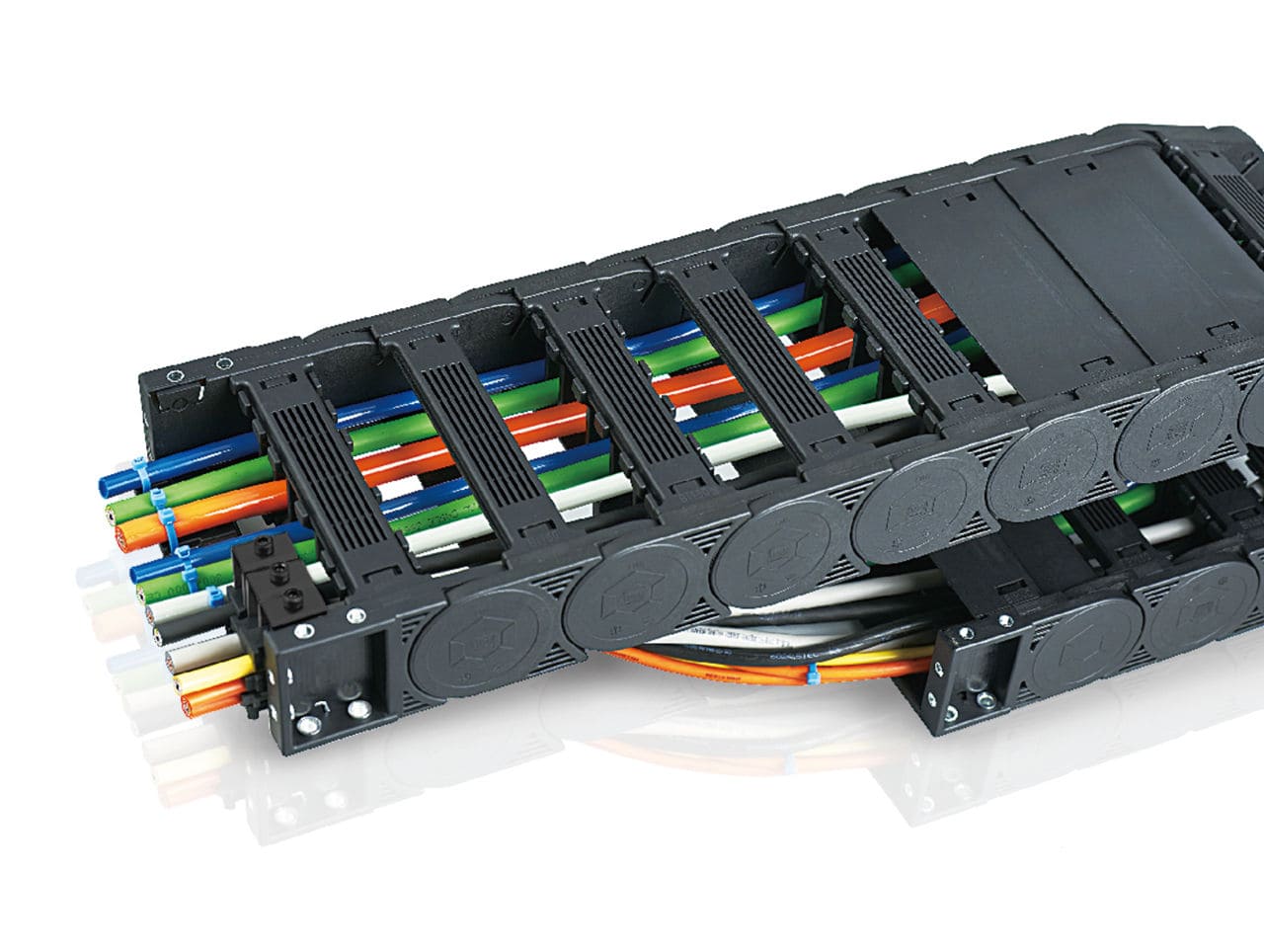

Embedded small drag chain

Quick Quote

Small drag chain with inner opening

Quick Quote

Semi-enclosed small drag chain

Quick Quote

Small drag chain with outer opening

Quick Quote

Small drag chain with external opening

Quick Quote

Semi-enclosed small drag chain with open outside

Quick Quote

Bridge type inner opening drag chain

Quick Quote

Bridge type double-sided opening drag chain

Quick Quote

Bridge-type inner opening drag chain

Quick Quote

Bridge-type expansion double-sided opening drag chain

Quick Quote

High-speed silent double-sided opening drag chain

Quick Quote

Closed double-sided opening drag chain

Quick Quote

Closed expansion double-sided opening drag chain

Quick Quote

Strain relief element

Quick Quote

Closed double-sided opening drag chain

Quick Quote

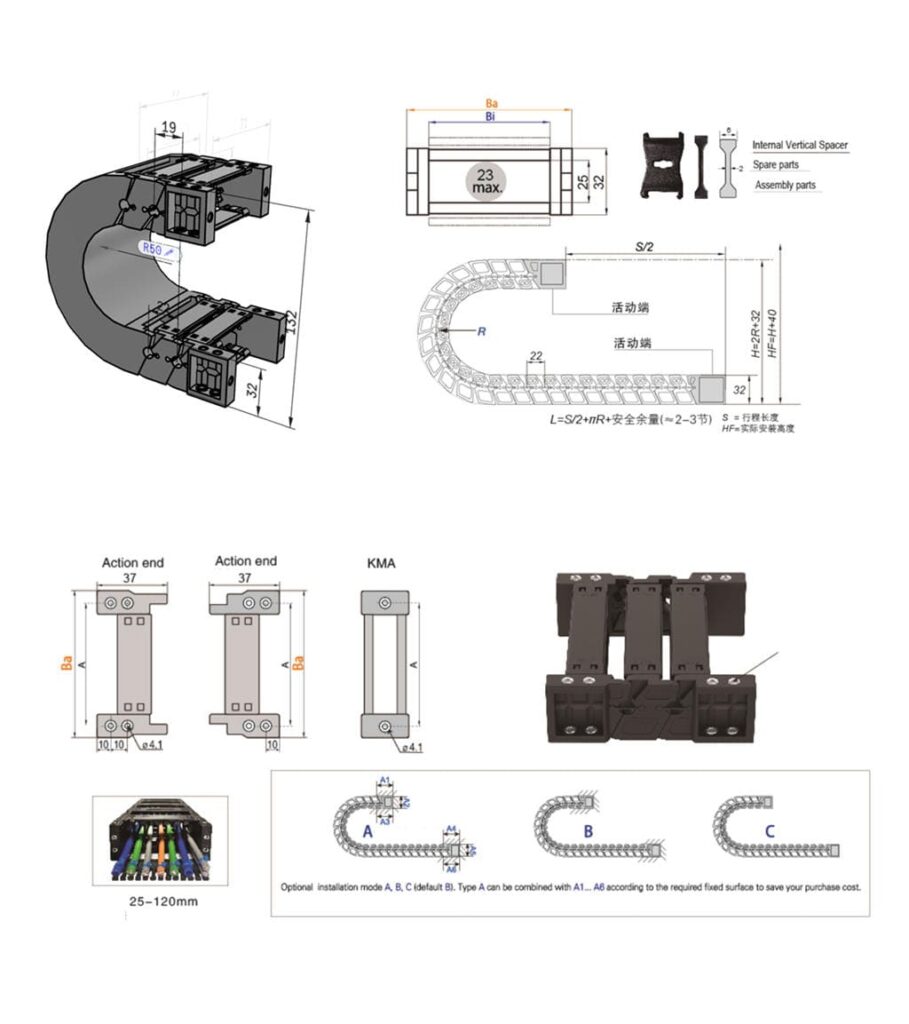

For more details of the above products, please contact us. You can also provide the application, inner width, inner height and bending radius of the drag chain you need, and we will recommend suitable products to you or customize them.

Whether you need a drag chain with medium-short stroke or medium-long stroke, light, fast and low noise or high load and high mechanical stress, linear motion, rotational motion or multi-axis motion, we can provide it for you. Our team will serve you wholeheartedly and solve your problems quickly, please do not hesitate to contact us immediately!

What Sets Us Apart

Excellent cost performance

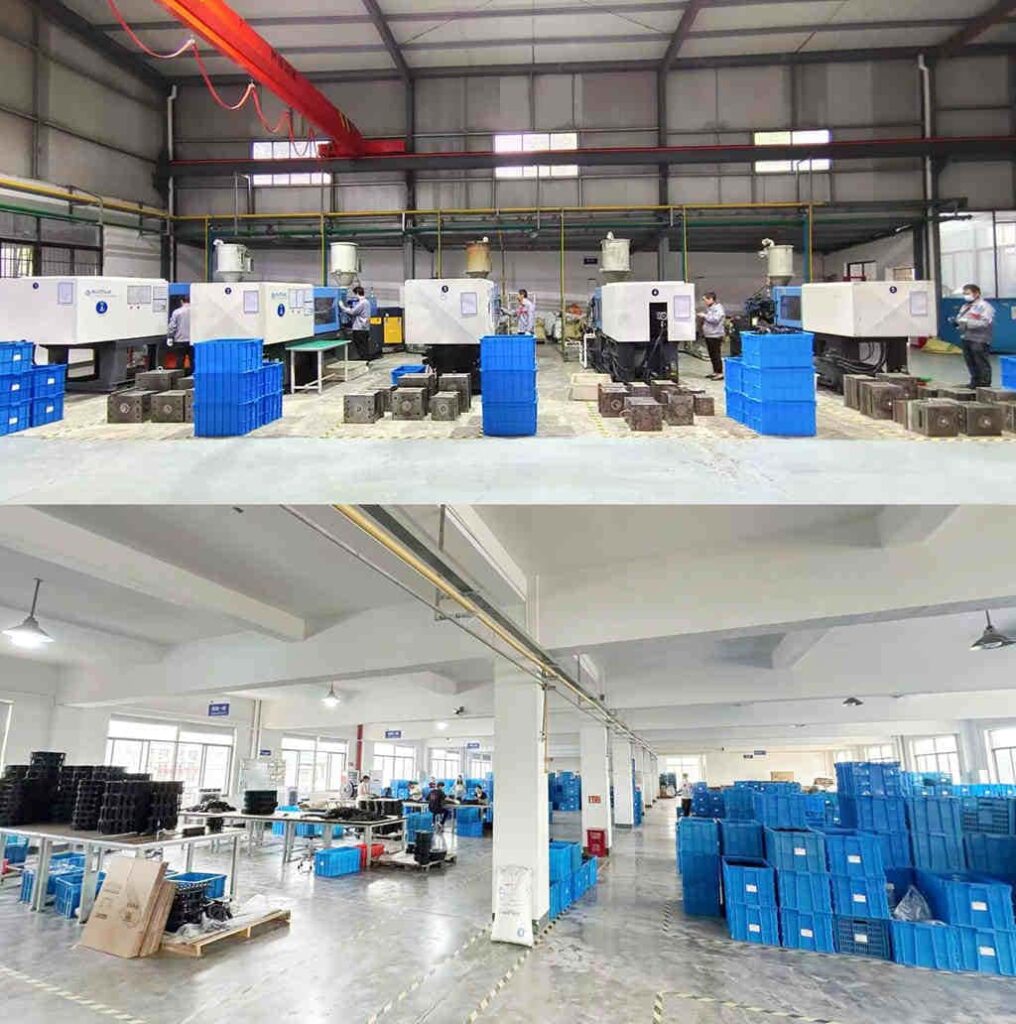

We are located in Yuyao, Zhejiang, the core hub of China’s plastics and mold industry, where the complete upstream, midstream and downstream industrial chain of high-end nylon drag chains is gathered.

From nylon raw materials, precision molds to finished product assembly, all key links are efficiently coordinated within a radius of 150 kilometers.

It is close to the two major international hub ports of Shanghai Port and Ningbo Port, providing seamless connection for global logistics. Combined with the large-scale centralized procurement model, while ensuring quality, the cost of raw materials, circulation costs and warehousing and logistics costs are all reduced to the lowest level in the industry.

Trustworthy quality

Our production system strictly follows international quality management standards and is certified by ISO 9001:2015.

Our drag chains are made of German brand reinforced nylon material, which has excellent toughness and fracture resistance.

Each drag chain must pass 10 million reciprocating motion tests to ensure that it remains silent at less than 45 decibels at a high speed of 5m/s, while meeting the UL94 V0 flame retardant rating and wide temperature range stability from -45℃ to 160℃.

Efficient production and quality control

We use fully automated injection molding production lines and intelligent control systems, equipped with high-precision injection molding equipment, combined with hot runner mold technology, which significantly shortens the molding cycle and reduces material loss. This combination of technologies enables our drag chain unit link molding accuracy to reach ±0.05mm, and the yield rate is stable at more than 99%, far exceeding the industry average.

Equipped with a complete set of testing equipment such as fatigue testing, salt spray testing, wear resistance testing, plus a quality inspection line, strict quality control management to ensure product quality.

Full support and service

Our professional technical team is always ready to provide personalized advice and quick assistance.

We can not only provide drag chains of various specifications and models, but also customize them according to your specific needs. Whether you provide drawings or specific requirements, we can provide you with the most suitable solution.

At the same time, we provide a variety of professional international logistics and transportation solutions to ensure the timely and intact delivery of goods.

Applications

Common applications of drag chains: Automated industrial equipment, medical equipment, automatic door machine systems, manipulators, printing machinery, woodworking machinery, photovoltaic manufacturing, machine tools, laser cutting and welding equipment, port machinery, car washing equipment, automated material handling systems, mining equipment, robots, food and beverage processing equipment.